Do you think Artificial Intelligence is a new technology? Nope. It’s nothing new.

But the pace at which it is improving and being adopted in all facets of development has never

been so swift.

Good ideas build and evolve gradually, eventually leading to a truly revolutionary breakthrough.

Thanks to Computer Vision, we are now on the cusp of another manufacturing revolution.

If you are someone who gets excited by these questions and loves reading tech-savvy stories where

companies come together to make a difference, then this story of Intel and SeeWise is just for

you.

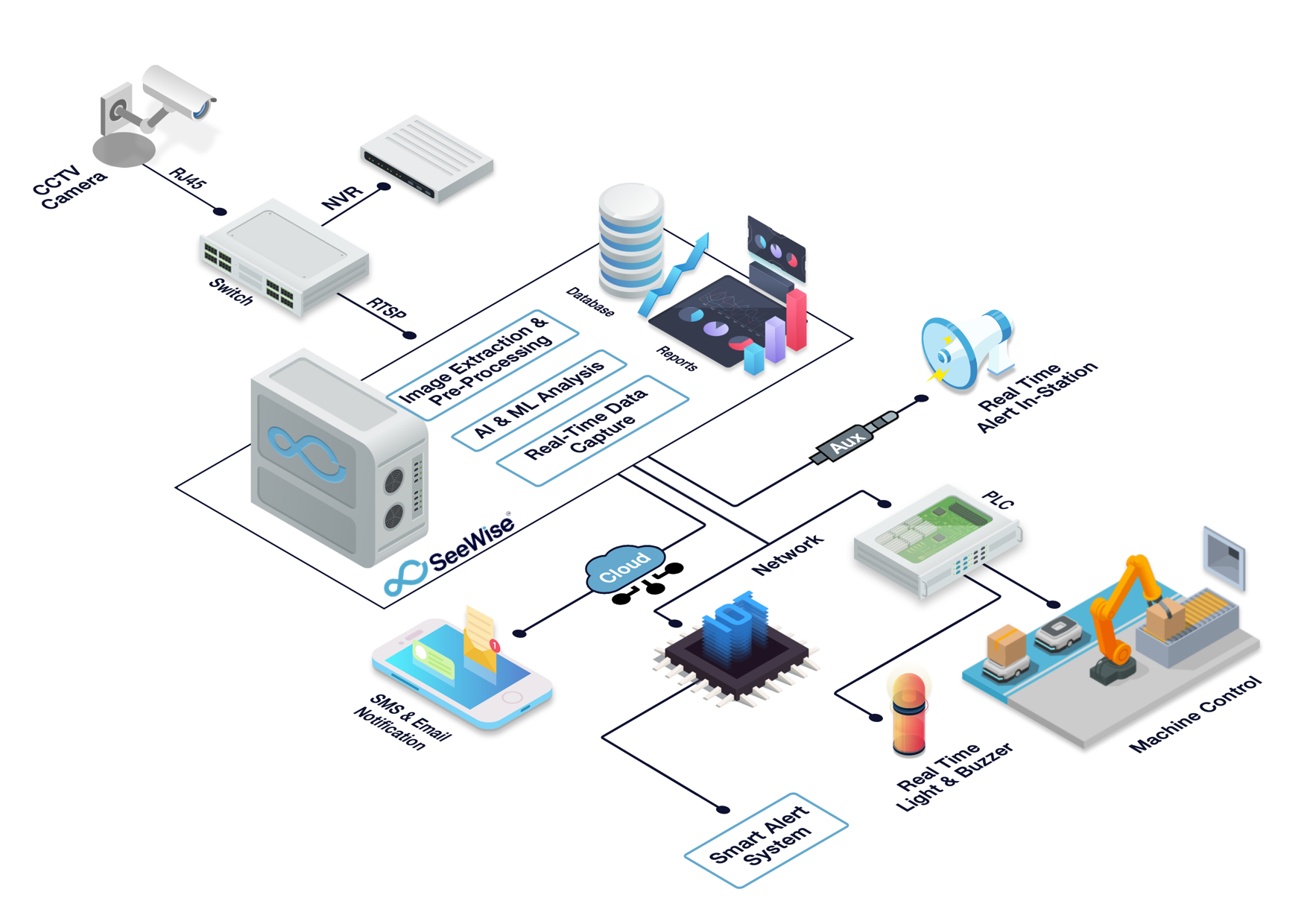

SeeWise is a real-time AI-powered smart factory solution using Computer Vision, Artificial

Intelligence, and Machine Learning technologies that enables business users to meticulously

monitor continuous and tireless 24x7 operation with the help of Smart digital cameras to alert

the ground staff when an exception is identified during the operation.

SeeWise is unlike any other computer vision provider existing in the market. As a truly

end-to-end solution, SeeWise can get you up and running quickly and seamlessly. Our Product is

crafted to meet the exact needs and can be trained to work in any specific environment.

That said, let us find out the overall picture of galvanizing industries today and figure out how

Intel and SeeWise leveraged AI and automation to tunnel a way for galvanizing industries to

track productivity.

A Look Into The Challenges Faced By Galvanizing Industries Today

A Galvanizing unit is where people and machines hustle together to coat metals (beams) with

molten Zinc. While all this might sound simplistic in words, when we look into the site

where the galvanizing process occurs, it is all busy and complicated: and even minute

negligence in following the steps and rules inside could affect the safety and security of

the unit and the overall quality of the end products produced. So, one of the most

influential factors that affect the productivity rate of a galvanizing unit is the lack of a

monitoring system that could capture everything that happens within the plant. That said,

here are some of the most common challenges faced by galvanizing industries while using

manual methods to track their productivity,

- Inefficiency in tracking human errors, machine availability, material availability,

defaults in the steps followed, etc.,

- Inaccuracies in the productivity data obtained from the manual records,

- Lack of a holistic outlook about what is happening inside the unit, etc.

So, to improve the productivity rate in these plants, we need to monitor and track every nook

and corner of the unit for better analytics.

And readers, this is where the SeeWise product and Intel-based OpenVINO platform make a

difference.

What is Intel OpenVINO Platform?

Intel OpenVINO is an efficient and multifaceted platform and a toolkit for developers working

on computer vision applications. OpenVINO stands for “Open Visual Inference and Neural

Network Optimization” and focuses on helping developers to take a write-once,

deploy-anywhere approach for optimizing neural network inference for Intel hardware

platforms. That said, Intel OpenVINO offers the privilege for developers to select models

and deploy pre-trained deep models.

Therefore, today, Intel OpenVINO has emerged as a handy toolkit for solving several tasks

relative to computer vision, automatic speech recognition, natural language processing, AI,

and Machine learning.

How Did The Intel OpenVINO Platform and SeeWise Smart AI Solution Help

Galvanizing Industries To Enhance Their Productivity And Safety?

When SeeWise started working on creating the customizable smart AI solution for galvanizing

plants, they found Intel OpenVINO to be one of the most appropriate tools to work with. From

offering a better processing environment to creating a smooth deployment process, Intel

OpenVINO made the overall development of the SeeWise Smart AI solution simple, easy, and

quick. Some of the striking features achieved by using Intel OpenVINO include

- An excellent running speed that is 2.5 times faster,

- An incredible FPS rate and an easy-to-integrate interface with other Intel Devices,

- Intel Cloud Developer made the application customizable in terms of architecture and

benchmarks per customer needs with an increased inference range of 3.5 times faster.

On the whole, Intel OpenVINO with 11gen Intel® Core™ i5 Processors made the SeeWise team take

a low code/no code approach to design and deploy a Smart AI solution for visual analytics

for various industries. From enhancing its overall performance to making it emerge as an

efficient solution for monitoring galvanizing plants, Intel has played a significant role in

the successful journey of making the SeeWise Visual Analytics Tool one of the most reliable

and capable solutions for galvanizing units to track productivity and performance today!

What is the ROI SeeWise and Intel achieved in bringing AI and automation to

galvanizing industries?

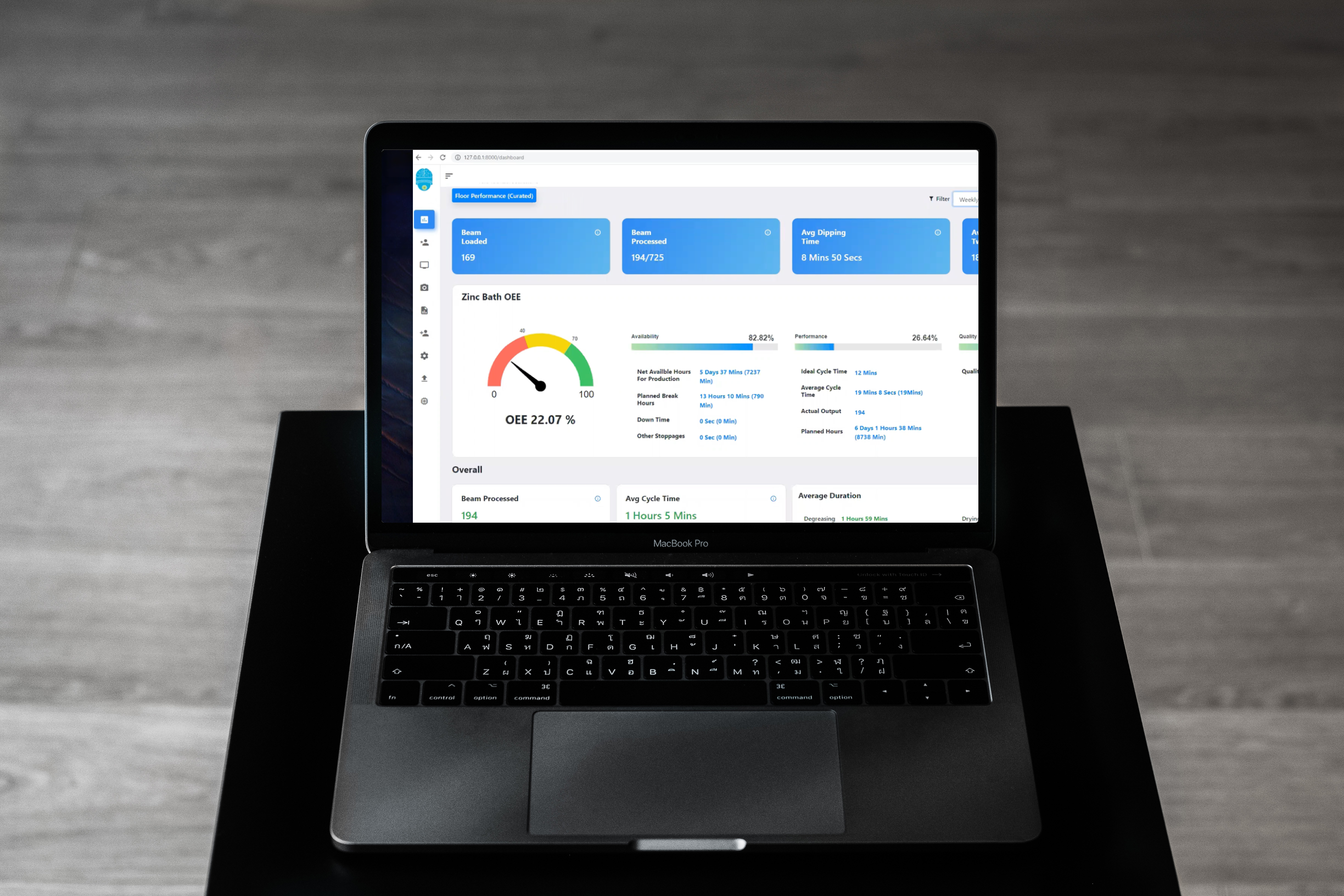

When the SeeWise and Intel-based Smart AI solution for visual analytics in galvanizing units

got implemented, the clients and the developers team had some enthralling results and

outcomes to be happy. Some of the noteworthy ROI they achieved include:

- Keen monitoring of the unit. From tracking material availability, machine downtime,

losses, and plant security to inspecting whether workers were following the safety

protocols and process sequence, SeeWise and Intel-based Smart AI solution gave all the

results as visual analytics for the supervising panel to make decisions.

- It gave a single dashboard and sent push notifications to the concerned monitoring team

to monitor, track, and make quick decisions based on the inputs.

- It tracked every minute parameters like Zinc bath temperature, acid concentration in

pickling, cycle time, etc., and reported them as insightful data on a centralized

dashboard.

- While this is something the solution was designed to find out, the increase in the

overall productivity of the galvanizing plants was one of the best outcomes SeeWise

achieved by using Intel OpenVINO in their Smart AI Solution

Therefore, this is how Intel and SeeWise came together to develop and customize one of the

most efficient Smart AI solutions for visual analytics generated from the video clips of

internal activities of a galvanizing unit.

SeeWise.AI helped

us to improve the over-all productivity and safety of our Galvanizing plant with-in

one month of their product implementation. The fact that we can visually see the data

points for improvement on minute by minute basis on real-time basis helped us to further

improve our internal process.

SeeWise.Ai also helped us to instantly locate the dependency of man and material needs

and address it immediately.

We are now working on implementing the SeeWise for our other 3 plants.

A leading manufacturer in Asia

How can you get started with improving the productivity and safety of your

galvanizing unit?

So, readers, this is how the SeeWise Smart AI solution and Intel OpenVINO Platform came

together to bring changes in tracking productivity and performance in galvanizing units.

That said, if you plan to leverage AI and automation tools to track and improve the

performance and productivity of your team at galvanizing plants, connect with us to get

expert insights!