Beyond Vision: How Seewise Integrates Data for Smarter,Actionable Solutions

Connecting the Dots: How Seewise Integrates Your Data for Actionable Insights

We've all seen vision systems popping up everywhere. Cameras watching machines, checking for problems – it's becoming the norm.

But let's be honest, a lot of these systems do the same thing: they collect data, maybe point out a problem, and that's about it. They tell you what happened, but not how to x it.

We Don't Just Think Outside the Box, We Redesign It

We don't just sell you a platform and walk away. We're not just about collecting data or even agging violations. We're about giving you, the person on the ground, the tools to actually solve the problem.

We're not saying we eliminate human error entirely. That's probably impossible. But we drastically minimize it. We give you the information you need, when you need it, in a way that's easy to understand and act on.

Case study

Not Just Seeing, But Stopping - Control your Machinery directly through our System

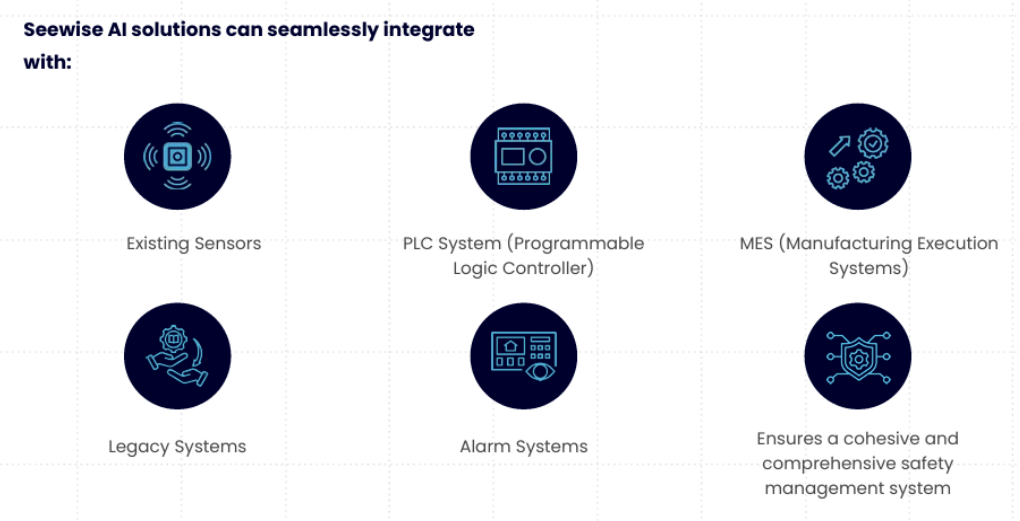

When it detects a critical violation – something that could put a worker at risk – it doesn't just send an alert. It can instantly communicate with the machine's PLC, HMI, and even the overarching MES system to trigger a controlled stop. This immediate intervention can prevent accidents before they happen. Because at the end of the day, human life is more important than anything else, and our technology is designed to protect it.

Seewise can be integrated directly with the machine's control system. If our system detects a person entering the designated safety area, it doesn't just sound an alarm. It can instantly trigger a controlled shutdown of the machine, preventing a potential collision and protecting workers. This isn't just reactive; it's proactive safety.

How AI Streamlines ERP & SAP Data for End Users

ERP and SAP systems are powerful tools. They hold tons of data, managing everything from inventory to nances. But sometimes, that data doesn't quite match up with what's happening on the ground. Think mismatched order quantities, incorrect stock levels.

These inconsistencies can lead to costly mistakes, wasted time, and frustrating delays. Imagine if you had a way to make your ERP/SAP data truly foolproof, giving your end-users clear, reliable insights. That's where our system integration comes in. We promise to reduce errors and save time, and make it foolproof.

Real-World OSHA Compliance - The Power of Localized Voice Alarms

Following OSHA guidelines, we can trigger targeted alerts using voice-based alarms in the operator's language, activate a brightly ashing tower lamp near the issue, or sound a distinct hooter/siren. This localized approach pinpoints the problem area instantly, allowing for swift corrective action by nearby personnel while minimizing disruption to ongoing operations.

Closing the Loop - How Seewise, MES, and VIN Integration Builds Trust in Car Manufacturing

In today's complex automotive manufacturing landscape, precision and traceability are non-negotiable.

Renowned car brands strive for excellence, not just in design and performance, but also in ensuring seamless production and data integrity. This is where the powerful synergy of Manufacturing Execution Systems (MES), Vehicle Identication Numbers (VIN), and our applications comes into play, creating a closed-loop system.

This closed-loop system ensures that no data is missed. Our system analyzes the visual data, compares it to the car's specic conguration, and sends its ndings back to the MES. This allows for real-time adjustments, immediate corrective actions, and comprehensive tracking. For a renowned car brand, this level of precision and data integrity is crucial in building and maintaining customer trust.

Seamless Integration for EHS Insights

Our system takes a holistic approach to EHS by monitoring crucial environmental factors. We track things like temperature and ventilation, ensuring they stay within optimum levels for a healthy and productive work environment. Beyond that, we also keep a close eye on waste, identifying areas where materials are being used inefciently. By integrating with various systems, we can pinpoint the source of the waste and help you make changes to reduce it.

Hooter Alarm - In the galvanizing industry, precision is paramount.

Imagine a galvanizing line where beams are dipped in the zinc bath. Our system monitors the process, tracking each beam's entry and calculating its retention time. This data isn't just stored

Here's where the magic happens: If a beam's retention time exceeds, it triggers a hooter alarm on the factory oor. This immediate, localized alert directly noties the crane operators for lifting the beam – to take action right now

Take the Next Step

Ultimately, Seewise’s integration capabilities are about more than just connecting systems. They're about connecting your vision to reality.

Unlike other platforms that stop at integration and data storage, we believe in the power of intelligent data mapping. Our system analyzes your integrated data, providing a clear path to understand.

Don't wait! Explore our resources, request a quote, or talk to our experts. Your journey to integrate and get the right insights starts here, Seewise